Tear Resistance: Ensuring Durability in Modern Materials

Introduction to Tear Resistance

Tear resistance is a fundamental property of materials, particularly in industrial applications where durability and reliability are critical. For industries such as Nidec DC Motors, where components are exposed to mechanical stresses, understanding tear resistance helps ensure that materials maintain their integrity under operational conditions.

Tear resistance measures a material’s ability to withstand the propagation of cracks or tears when subjected to force. This property is essential not only for safety but also for long-term performance, reducing maintenance needs and avoiding costly downtime.

Importance of Tear Resistance in Industrial Applications

In industrial settings, materials face various mechanical forces, environmental stressors, and repeated use. Tear resistance is critical in such scenarios for several reasons:

- Safety: Materials with low tear resistance may fail unexpectedly, leading to accidents or equipment damage.

- Longevity: High tear resistance contributes to longer service life and reduces the need for frequent replacements.

- Performance Reliability: Ensures that components, such as insulation materials, protective coatings, and conveyor belts, perform consistently under stress.

- Cost Efficiency: Materials with higher tear resistance reduce maintenance and replacement costs over time.

In industries like manufacturing, automotive, and electronics, ensuring proper tear resistance is a key factor in material selection and design.

Factors Affecting Tear Resistance

Tear resistance depends on various factors, including material composition, structure, and environmental conditions. Key influences include:

- Material Type: Metals, polymers, composites, and textiles all exhibit different tear resistance characteristics. For example, polymers may stretch and deform before tearing, while metals may fracture more abruptly.

- Thickness and Density: Thicker and denser materials generally show higher tear resistance.

- Manufacturing Process: Processes such as extrusion, molding, and lamination can impact the material’s structural integrity and tear resistance.

- Environmental Conditions: Exposure to heat, moisture, UV radiation, or chemicals can reduce tear resistance over time.

- Load Direction: The direction in which force is applied can influence how and where tears propagate in the material.

Understanding these factors helps engineers design and select materials that meet operational demands while maintaining safety and efficiency.

Testing Tear Resistance

Evaluating tear resistance involves standardized tests to determine a material’s ability to resist tearing under controlled conditions. Common testing methods include:

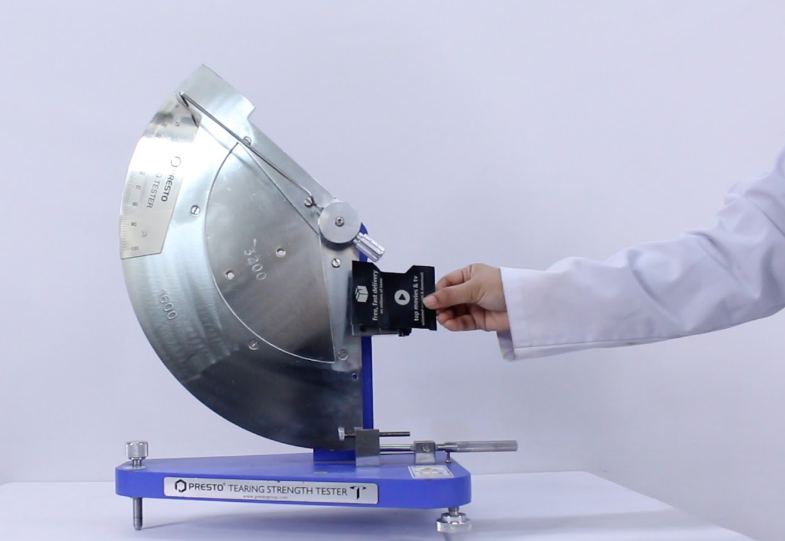

Elmendorf Tear Test

The Elmendorf tear test measures tear resistance by applying a pendulum to a pre-cut sample and recording the energy required to propagate the tear. It is widely used for textiles, films, and flexible materials.

Trouser Tear Test

In the trouser tear test, a specimen is cut into a shape resembling a pair of trousers, and the legs are pulled apart to measure tear resistance. This method is suitable for thin materials like plastic films and fabrics.

Single Edge Notch Test

This method involves creating a notch in the material and applying tension until the tear propagates. It is often used for polymers, composites, and rubber materials.

Standardization

Tests for tear resistance follow international standards such as ASTM, ISO, and DIN to ensure consistency and comparability. Examples include ASTM D624 for rubber, ISO 6383 for textiles, and ASTM D1938 for thin plastic films. Adhering to these standards ensures reliable and repeatable results.

See also: Medical Software for Healthcare Providers: Enhancing Care Through Technology

Applications of Tear Resistance

High tear resistance is crucial in a wide range of applications. Some notable examples include:

- Automotive Industry: Materials used in insulation, gaskets, and protective coverings must resist tearing to maintain safety and performance.

- Aerospace Industry: Aircraft components, such as protective coatings and fabric-based structures, require high tear resistance to withstand operational stress.

- Electronics and Motors: Components in DC motors, including protective films and insulating materials, benefit from high tear resistance to prevent mechanical failures.

- Textile Industry: Fabrics used in protective clothing, industrial coverings, and conveyor belts must maintain integrity under repeated stress.

- Packaging Materials: Packaging films and bags require sufficient tear resistance to prevent damage during handling and transport.

By understanding and optimizing tear resistance, engineers and designers can improve product reliability and extend the service life of components.

Enhancing Tear Resistance

Manufacturers and material scientists employ several strategies to enhance tear resistance:

- Material Blending: Combining different polymers or fibers can improve tear resistance while maintaining flexibility.

- Reinforcements: Incorporating reinforcing elements such as fibers, meshes, or laminates enhances the material’s structural strength.

- Surface Treatments: Coatings and chemical treatments can improve resistance to environmental degradation, such as UV exposure or chemical attack.

- Optimized Design: Adjusting the geometry, thickness, and layering of components can reduce stress concentration points and enhance tear resistance.

These strategies ensure that materials meet the rigorous demands of industrial applications, particularly in environments where mechanical stress is frequent.

Challenges in Tear Resistance

Despite advances in material science, achieving high tear resistance presents several challenges:

- Balancing Flexibility and Strength: Highly tear-resistant materials may become rigid, reducing flexibility and adaptability.

- Environmental Degradation: Exposure to harsh conditions can weaken materials, necessitating protective measures.

- Manufacturing Limitations: Certain processes may introduce micro-defects that reduce tear resistance.

- Cost Considerations: High-performance materials with superior tear resistance can be more expensive, requiring careful cost-benefit analysis.

Addressing these challenges requires careful material selection, testing, and engineering design to ensure both performance and cost-effectiveness.

Conclusion

Tear resistance is a critical property that ensures the durability, reliability, and safety of materials in industrial applications. By understanding the factors affecting tear resistance and employing standardized testing methods, engineers can select and optimize materials to meet the demands of modern infrastructure and equipment.

In industries such as Nidec DC Motors, high tear resistance contributes to long-lasting components, reduces maintenance costs, and ensures operational safety. Whether in automotive, aerospace, electronics, or packaging, tear resistance is a key factor in material performance and overall project success.

Investing in proper tear resistance testing and material optimization allows companies to achieve efficiency, reliability, and sustainability, ultimately enhancing product quality and operational excellence.